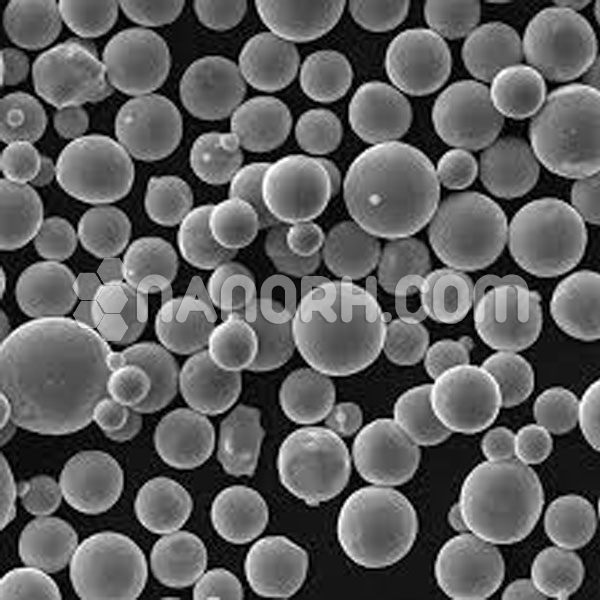

| AZ91D alloy powder spherical | |

| Product No | NRE-60102 |

| Purity | 99.9% |

| Mesh | 15-53 mesh |

| Color | Silver Gray |

| AZ91D | |||||||||

| Composition | Mg | Al | Cu | Fe | Mn | Ni | Si | Zn | Be |

| wt% | 90.43 | 8.90 | 0.0006 | 0. 0112 | 0.19 | 0.003 | 0.003 | 0.4278 | 0.00098 |

AZ91D alloy powder spherical

Applications

Additive Manufacturing (3D Printing):

Processes: Selective Laser Melting (SLM), Electron Beam Melting (EBM), Direct Energy Deposition (DED)

Applications:

Aerospace: Lightweight structural components, brackets, and engine parts.

Automotive: High-performance parts such as engine components, transmission systems, and chassis components.

Medical: Custom prosthetics, implants, and orthopedic devices where lightweight and strength are crucial.

Advantages: The spherical AZ91D alloy powder improves flowability and density, leading to higher-quality prints with complex geometries, making it ideal for producing functional, lightweight, and high-strength components.

Powder Metallurgy (PM):

Applications:

Automotive: Structural components, gears, and bearings, contributing to weight reduction and enhanced fuel efficiency.

Aerospace: Lightweight, high-strength parts such as structural brackets and components exposed to mechanical stress.

Advantages: The spherical powder improves the sintering process, creating high-density, durable parts with minimal porosity, improving the strength-to-weight ratio of the final product.

Thermal Spray Coatings:

Applications:

Corrosion protection: For components exposed to harsh environments, such as in marine, automotive, and aerospace industries.

Wear-resistant coatings for components such as turbines, molds, and machine tools.

Process: Thermal spraying techniques like plasma spraying, flame spraying, and HVOF (High-Velocity Oxygen Fuel) are used to apply AZ91D coatings, offering corrosion resistance and wear protection.

Advantages: AZ91D alloy powder coatings provide excellent durability and protection against corrosion, particularly in extreme environments like marine and industrial settings.

Die-Casting:

Applications:

Automotive: Lightweight magnesium die-castings for engine blocks, wheels, transmission components, and brackets.

Aerospace: Magnesium castings for lightweight structural components in aircraft.

Advantages: The castability of AZ91D enables the creation of thin-walled, complex parts with high dimensional accuracy and minimal porosity, all while maintaining the alloy’s strength and corrosion resistance.

Metal Injection Molding (MIM):

Applications:

Automotive: Small, intricate parts like connectors, brackets, and fasteners.

Medical: Precision components such as dental implants and surgical tools.