| Mg-Zn alloy Spherical powder | |

| Product No | NRE-60101 |

| Purity | 99.9% |

| Mesh | 30-500 mesh |

| Color | Silver Gray |

| Product | Ratio Mg: Zn | Real density(g/cm³) | Calorific value(J/g) |

|

Atomized spherical Mg-Zn alloy powder |

70:30 | 2.26 | 18110 |

| 30:70 | 3.47 | 11180 | |

| 50:50 | 2.83 | 15050 | |

| 20:80 | 4.23 | 9240 | |

| 10:90 | 5.25 | 7300 | |

| 90:10 | 1.92 | 24110 | |

| 95:5 | 1.82 | 24136 |

Mg-Zn alloy Spherical powder

Introduction

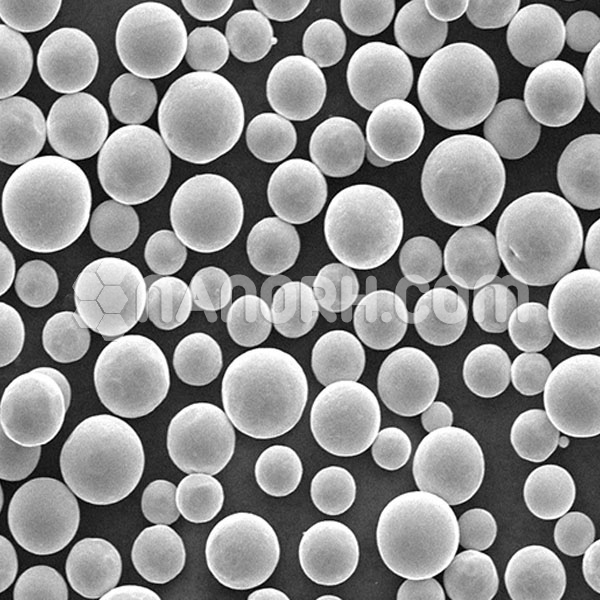

Spherical Magnesium-Zinc (Mg-Zn) alloy powder is a specialized material made by combining magnesium (Mg) with zinc (Zn) in varying proportions, produced in spherical form through atomization processes. The spherical shape of the powder particles enhances their flowability, uniformity, and packing density, making them ideal for a wide range of powder-based manufacturing techniques, including additive manufacturing, powder metallurgy, and thermal spraying.

Key Features

Lightweight:

Magnesium is the lightest structural metal, and the addition of zinc maintains the low density of the alloy. This makes Mg-Zn alloy powder ideal for applications where reducing weight is crucial, such as in the automotive and aerospace industries.

Corrosion Resistance:

Zinc improves the corrosion resistance of magnesium alloys, making them more suitable for harsh environments. This is particularly important for applications exposed to moisture, saltwater, or chemical exposure, such as in marine, automotive, and aerospace components.

High Strength-to-Weight Ratio:

Mg-Zn alloys provide an excellent combination of strength and low weight, making them suitable for structural components that require both lightweight and high strength, such as engine parts, wheels, and chassis components.

Thermal Conductivity:

Magnesium alloys generally have good thermal conductivity, which is important for applications in heat dissipation systems. The alloy’s thermal properties make it ideal for electronic components and battery enclosures.

Spherical Powder Shape:

The spherical shape of Mg-Zn alloy powder enhances its flowability and packing efficiency, making it easier to handle in processes like metal injection molding (MIM), powder metallurgy (PM), and 3D printing.