| Spherical Aluminum based alloy powder | |

| Product No | NRE-60100 |

| Purity | 99.9% |

| Mesh | 30-500 mesh |

| Color | Silver Gray |

AlZn8020

|

Composition |

wt. (%) | |||||||

| Zn | Fe | Si | Cu | Ti | Mg | Mn | Al | |

| 19.055% | 0.095% | 0.033% | 0.01% | 0.005% | 0.01% | 0.02% | balance | |

AlZn9010

|

Composition |

wt. (%) | |||||||

| Zn | Fe | Si | Cu | Ti | Mg | Mn | Al | |

| 0.095% | 0.095% | 0.033% | 0.01% | 0.005% | 0.01% | 0.02% | balance | |

Theoretical density and combustion heat

| Sample

(g/cm³) |

Theoretical density

(g/cm³) |

Combustion Heatk

(J/g) |

Calculated value according to alloy ratio (J/g) |

| Al-Zn9010-6μm | 2.87 | 26.61 | 26.76 |

| Al-Zn8020-6μm | 3.08 | 23.42 | 24.38 |

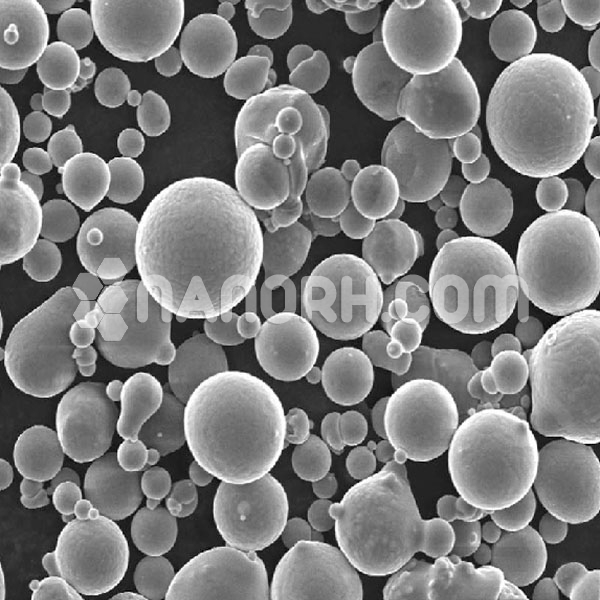

Spherical Aluminum based alloy powder

Spherical aluminum-based alloy powder is a specialized material made by combining aluminum with various alloying elements such as copper, silicon, magnesium, zinc, or manganese. These alloys are processed through atomization or other powder production techniques, which result in spherical-shaped powder particles. The spherical shape is particularly desirable because it improves the flowability, packing density, and uniformity of the powder, making it ideal for advanced manufacturing processes like additive manufacturing (3D printing), powder metallurgy, and metal injection molding (MIM).

Key Features:

Lightweight:

Aluminum is one of the lightest metals used in structural applications, making aluminum-based alloys ideal for creating lightweight components. This is particularly beneficial in industries like aerospace and automotive, where weight reduction improves performance, fuel efficiency, and overall efficiency.

Corrosion Resistance:

Aluminum alloys, especially those containing elements like silicon or magnesium, offer superior corrosion resistance. This makes them ideal for applications exposed to harsh environments, such as marine, automotive, and construction components, where parts are subject to moisture, saltwater, or chemicals.

High Strength-to-Weight Ratio:

The high strength-to-weight ratio of aluminum-based alloys allows for the creation of strong, durable parts that do not compromise on weight. This makes these alloys ideal for structural components in the aerospace and automotive industries, where both strength and weight reduction are critical.

Good Thermal and Electrical Conductivity:

Aluminum alloys maintain excellent thermal and electrical conductivity, which is especially important for electronics, batteries, and heat dissipation systems. This property makes aluminum-based alloys suitable for heat sinks, electrical enclosures, and other thermally sensitive applications.