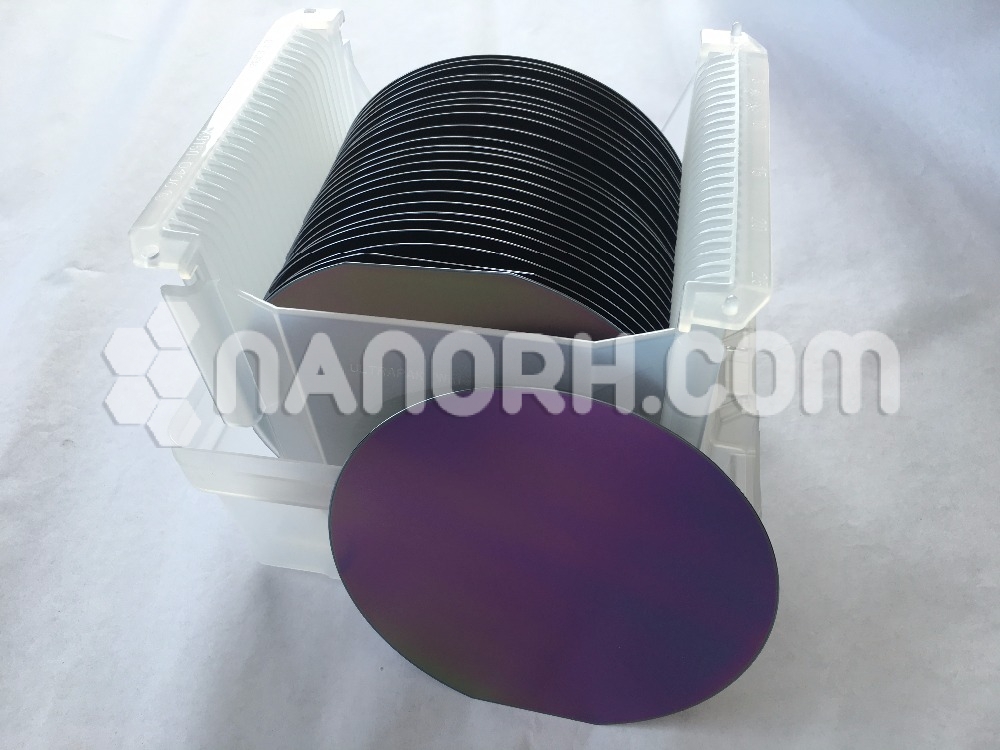

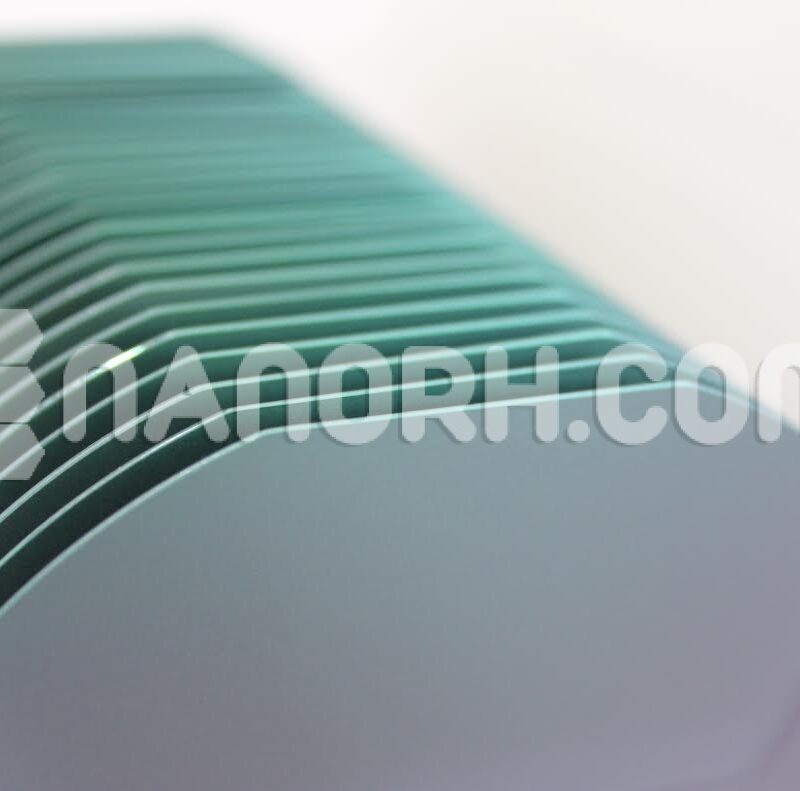

| Silicon Wafer Gold Coated | |

| Product No | NRE-44030 |

| CAS | NA |

| Type | NA |

| Crystal method | NA |

| Coating | Gold Coating |

| Diameter (mm) | 4” (101.6mm) |

| Thickness | 275 μm |

| RRG (%) | ≤12 % |

| Crystal Orientation | <100> |

| Oxygen Contents | 12.5-16.5 ppma |

| Carbon Contents | ≤1 ppma |

Silicon Wafer Gold Coated

Introduction:

Silicon wafer gold coated substrates that have been coated with a thin layer of gold. This specialized treatment enhances the properties of the silicon wafer, making it suitable for a range of advanced applications. Gold is chosen for its excellent electrical conductivity, corrosion resistance, and ability to form stable and reliable contacts with silicon.

Applications:

Semiconductor Devices:

Gold coatings provide effective electrical contacts in various semiconductor devices, ensuring reliable connections and improved performance in integrated circuits (ICs).

Microelectromechanical Systems (MEMS):

In MEMS fabrication, gold coatings can be used for electrical interconnects, enhancing device reliability and performance. They are particularly useful in sensors and actuators.

Optoelectronics:

Gold-coated wafers are used in optoelectronic applications, such as light-emitting diodes (LEDs) and photodetectors, where efficient light coupling and electrical connectivity are essential.

Biomedical Applications:

The biocompatibility of gold makes these wafers suitable for use in biosensors and other biomedical devices. They can facilitate improved signal transduction and biological interactions.

Surface Plasmon Resonance (SPR) Sensors:

Gold coatings enable SPR techniques for biosensing applications. These sensors leverage the unique optical properties of gold to detect biological interactions at very low concentrations.

Research and Development:

In laboratory settings, gold-coated silicon wafers are often used in research involving surface chemistry, nanotechnology, and material science, providing a stable platform for experimentation.