| Zirconium Sputtering Target | |

| Product No | NRE-43188 |

| CAS No. | 7440-67-7 |

| Formula | Zr |

| Molecular Weight | 91.224 g/mol |

| Purity | >99.99% |

| Density | 6.52 g/cm³ |

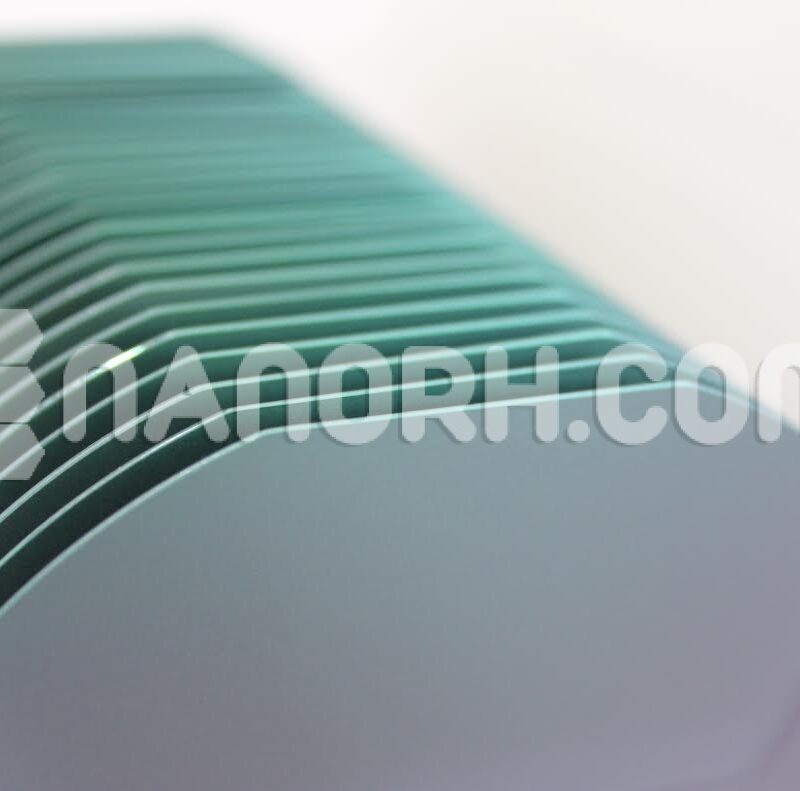

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Zirconium Sputtering Target

Introduction

Zirconium sputtering target are materials used in physical vapor deposition (PVD) processes to create thin films of zirconium on various substrates. Zirconium is a transition metal known for its excellent corrosion resistance, high melting point, and good mechanical properties. These attributes make zirconium sputtering targets essential in various industrial applications, particularly in the semiconductor and coatings industries.

Applications

Semiconductor Manufacturing: Zirconium is used to deposit thin films for microelectronics, including gate electrodes and interconnects. Its properties help improve device performance and reliability.

Optical Coatings: Zirconium films can serve as protective coatings on optical devices, enhancing durability and providing anti-reflective or reflective properties in lenses and mirrors.

Biomedical Applications: Due to its biocompatibility, zirconium is often used in coatings for medical devices and implants, promoting better integration with biological tissues.

Hard Coatings: Zirconium is known for its hardness and wear resistance, making it suitable for protective coatings on cutting tools and other machinery that require enhanced durability.

Thermal Barrier Coatings: In aerospace applications, zirconium films are used as thermal barrier coatings (TBCs) to protect components from high temperatures, improving overall efficiency.

Nuclear Applications: Zirconium is widely used in the nuclear industry due to its low absorption cross-section for thermal neutrons, making it suitable for cladding materials in nuclear reactors.