| Titanium Aluminium Vanadium Sputtering Target | |

| Product No | NRE-43157 |

| CAS No. | NA |

| Formula | TiAlV |

| Molecular Weight | NA |

| Purity | >99.99% |

| Density | NA |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

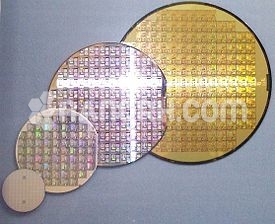

Titanium Aluminium Vanadium Sputtering Target

Introduction:

Titanium aluminium vanadium sputtering targets are intermetallic compounds known for their exceptional mechanical properties, high strength-to-weight ratio, and excellent resistance to heat and corrosion. The addition of vanadium enhances the overall performance of the alloy, making it suitable for a variety of advanced applications. Sputtering is an effective method for depositing thin films of TiAlV, enabling precise control over the film’s composition and microstructure.

Applications

Aerospace of Components:

TiAlV alloy are extensively used in the aerospace industry for components such as turbine blades and engine casings, where lightweight and high-temperature resistance are crucial.

Automotive Parts:

In the automotive sector, TiAlV is employed in high-performance engine components, such as valve springs and connecting rods, contributing to improved fuel efficiency and performance.

Cutting Tools and Coatings:

TiAlV coatings are applied to cutting tools, enhancing their wear resistance and extending tool life. This is particularly beneficial in high-speed machining applications.

Biomedical Implants:

The biocompatibility of TiAlV makes it suitable for medical devices and implants, where corrosion resistance and mechanical strength are essential for long-term performance.

Additive Manufacturing:

TiAlV alloy are increasingly being explored in additive manufacturing (3D printing), allowing for the production of complex geometries for high-performance components in aerospace and automotive applications.

Optical Coatings:

Thin films of TiAlV can be used in optical applications, such as anti-reflective coatings for lenses and mirrors, enhancing performance while providing protection.

Electronic Devices:

TiAlV can be utilized in electronic applications, including thin-film transistors (TFTs) and other semiconductor devices, benefiting from its electrical and thermal properties.

Research and Development:

TiAlV sputtering targets are also employed in academic and industrial research to explore new materials and coatings, contributing to advancements in material science.

Sputtering Process

The sputtering process for titanium aluminium vanadium involves using a TiAlV target in a vacuum chamber. Energetic ions bombard the target, dislodging atoms that are then deposited onto a substrate.