| Stainless Steel Sputtering Target | |

| Product No | NRE-43144 |

| CAS No. | 65997-19-5 |

| Formula | SS |

| Molecular Weight | NA |

| Purity | >99.99% |

| Density | NA |

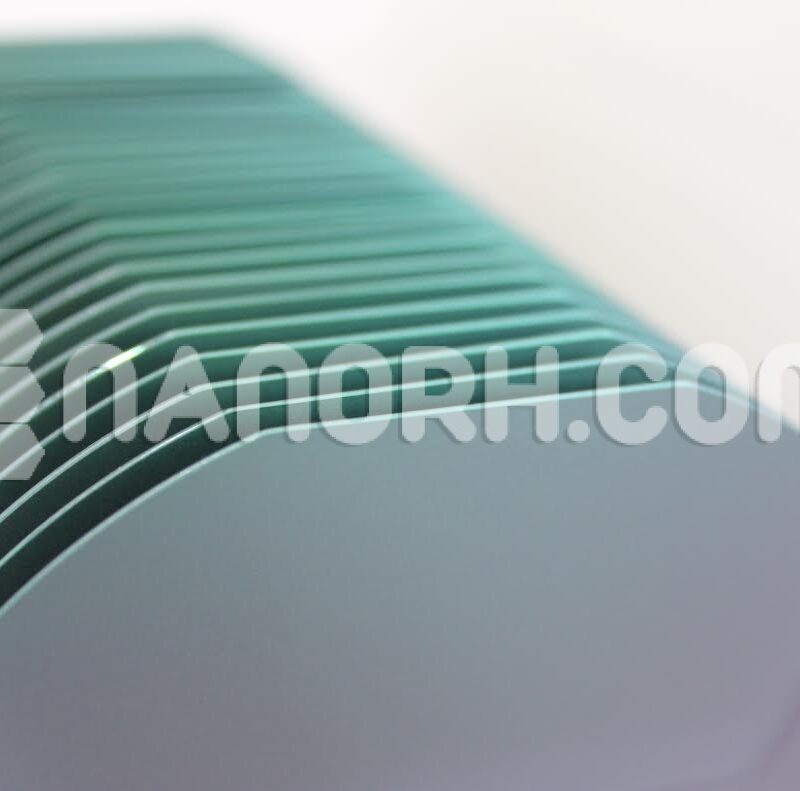

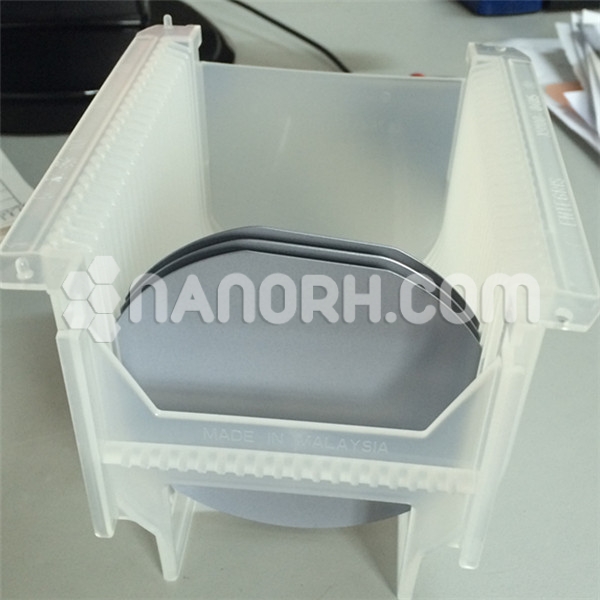

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | NA |

| Resistivity | NA |

| Thermal Conductivity | NA |

Stainless Steel Sputtering Target

Introduction:

Stainless steel sputtering target are materials widely used in the sputtering process for thin film deposition. Stainless steel is an alloy primarily composed of iron, chromium, and, in some cases, nickel and other elements, which provide it with excellent corrosion resistance, strength, and durability. These properties make stainless steel an ideal choice for various applications in electronics, optics, and protective coatings.

Applications:

Protective Coatings:

Application: Stainless steel films are used to provide protective coatings for a variety of substrates.

Significance: These coatings enhance resistance to corrosion, wear, and environmental factors, making them ideal for use in harsh conditions.

Electronic Components:

Application: Used in the deposition of conductive and non-conductive layers in electronic devices.

Significance: Stainless steel films can serve as barriers or interconnects, contributing to the performance and reliability of semiconductor devices.

Optical Coatings:

Application: Employed in the production of optical coatings for mirrors and lenses.

Significance: Stainless steel can enhance durability while providing desired optical properties, making it suitable for various optical applications.

Biomedical Applications:

Application: Stainless steel sputtered films are used in medical devices and implants.

Significance: Their biocompatibility and corrosion resistance are crucial for ensuring the longevity and safety of medical implants.

Decorative Coatings:

Application: Stainless steel thin films are used for decorative purposes in consumer products.

Significance: These coatings provide an attractive finish while also enhancing the durability of products like jewelry and household items.

Magnetic Applications:

Application: Used in the creation of magnetic thin films for sensors and data storage.

Significance: Stainless steel films can be engineered to exhibit specific magnetic properties for various technological applications.

Energy Applications:

Application: Employed in thin-film solar cells and other renewable energy technologies.

Significance: Stainless steel can act as a conductive layer, improving the efficiency of energy harvesting devices.