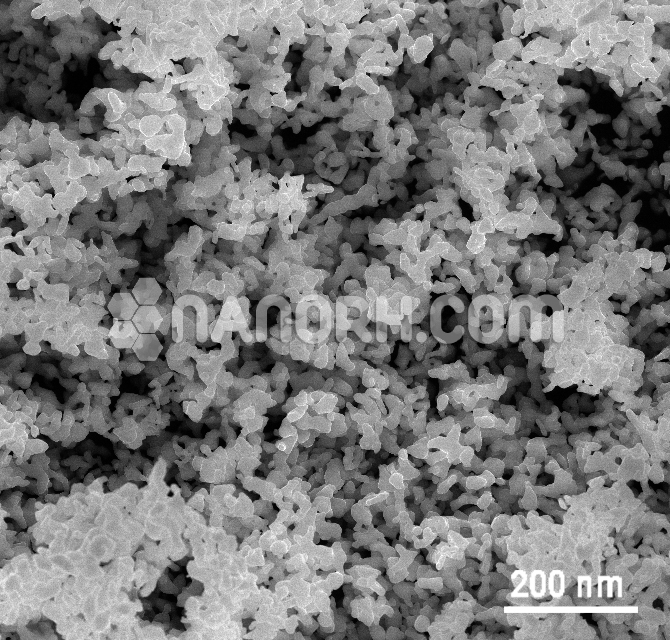

Nickel Based Fluxed Alloy Nanoparticles

Product No: NRE-2063

| Nickel Based Fluxed Alloy Nanoparticles | Grade | Chemistry | Size | Hardness |

| NiCrBSiFe Atomized | Ni20A | C:0.1;Si:3;B:1;Cr:1;Fe≤6;Ni:Bal | APS<100nm | 20 |

| Ni40A | C:0.3;Si:3;B:2;Cr:10,Fe≤15;Ni:Bal | APS<100nm | 40 | |

| Ni45 | C:0.4;Si:3;B:2.6;Cr:12;Fe≤15;Ni:Bal | APS<100nm | 45 | |

| Ni60 | Cr:18.5,Si:4.2,Fe:4.2,

B:3.3,C:0.7,Ni:Rem. |

APS<100nm | 60 |

Nickel Based Fluxed Alloy Nanoparticles

Introduction

Nickel-based fluxed alloy nanoparticles refer to nanoparticles composed primarily of Nickel (Ni) combined with various fluxing agents or alloying elements. Fluxing agents are substances that help facilitate metal alloying, fusion, or processing by reducing the oxidation of metals and ensuring better flow during various processes. These fluxed alloys are typically designed to enhance properties such as corrosion resistance, thermal stability, mechanical strength, and electrical conductivity.

Properties of Nickel-Based Fluxed Alloys

Corrosion Resistance: The addition of fluxing agents or alloying elements often enhances the corrosion resistance of nickel-based alloys, especially in harsh environments such as marine, chemical, or high-temperature industrial settings.

Thermal Stability: Fluxed nickel alloys show strong resistance to high-temperature oxidation and retain their mechanical properties at elevated temperatures, making them ideal for high-performance applications.

Strength and Toughness: Nickel, being a highly versatile metal, offers good strength, ductility, and toughness. The fluxed alloys improve these properties further, especially in extreme environments.

Catalytic Activity: In certain applications, fluxed nickel alloys exhibit enhanced catalytic properties, making them suitable for chemical reactions or energy applications.

Synthesis

Mechanical Alloying (Ball Milling): By blending fine powders of nickel with fluxing agents or other alloying elements, ball milling allows for the creation of homogeneously mixed nanoparticles. This process ensures that the fluxed alloy nanoparticles have uniform size and distribution.

Chemical Vapor Deposition (CVD): In CVD, gaseous metal precursors react on a heated substrate, forming thin films or nanoparticles.

Sol-Gel Process: The sol-gel method involves the formation of a gel from precursor solutions of nickel and fluxing agents. The gel is then heat-treated to form nanoparticles. This approach offers flexibility in controlling particle size and alloy composition.

Hydrothermal Synthesis: This method uses high-pressure water or other solvents to facilitate chemical reactions between nickel and alloying elements. This process leads to the formation of well-structured nanoparticles that are highly crystalline.

Electrochemical Deposition: Electrochemical techniques are employed to deposit nickel-based fluxed alloy nanoparticles onto substrates or into solutions. This method provides high purity and uniformity in the alloy composition.