| Zirconium Iron Alloy Sputtering Targets | |

| Product No | NRE-43618 |

| CAS No. | NA |

| Formula | Zr-Fe |

| Molecular Weight | NA |

| Purity | >99.9% |

| Density | NA |

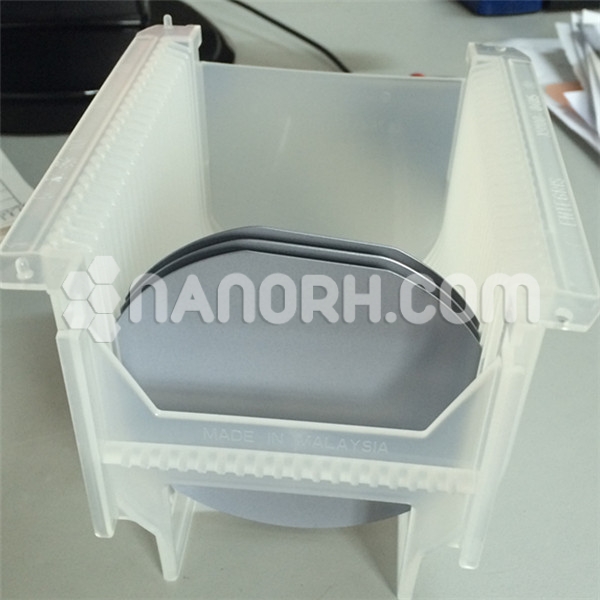

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Zirconium Iron Alloy Sputtering Targets

Introduction

Zirconium iron alloy sputtering targets are characterized by a combination of desirable properties from both elements, including zirconium’s corrosion resistance and strength, and iron’s magnetic and mechanical characteristics. These alloys are particularly useful in applications requiring enhanced performance under challenging conditions. Sputtering targets made from zirconium-iron alloys are employed in thin-film deposition processes, providing unique properties that can be tailored for specific applications.

Applications

Magnetic Coatings:

Used in the deposition of magnetic thin films for applications in data storage devices, sensors, and other electronic components where magnetic properties are critical.

Corrosion-Resistant Coatings:

Employed in environments where resistance to oxidation and corrosion is essential, benefiting from zirconium’s protective qualities.

Semiconductor Manufacturing:

Used to create conductive layers in semiconductor devices, where the alloy’s properties can enhance performance and reliability.

Optical Coatings:

Applied in the production of thin films for optical components, helping to improve durability and performance in lenses and mirrors.

Biomedical Applications:

Investigated for use in medical implants and devices, where zirconium’s biocompatibility and strength are advantageous.

Nanoscale Applications:

Supports the development of nanostructured materials, where precise control over film properties is essential for advanced applications.

Thermal Coatings:

Used in high-temperature environments, providing thermal stability and resistance to wear.