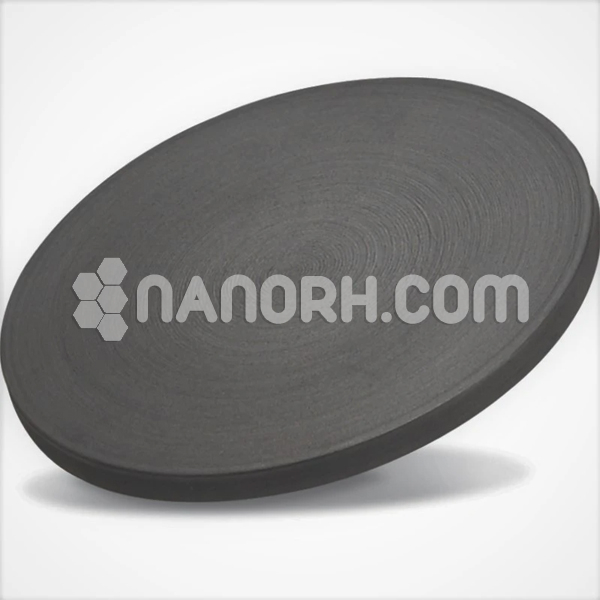

| Tin Tantalate Sputtering Targets | |

| Product No | NRE-43574 |

| CAS No. | NA |

| Formula | SnTa2O6 |

| Molecular Weight | NA |

| Purity | >99.9% |

| Density | NA |

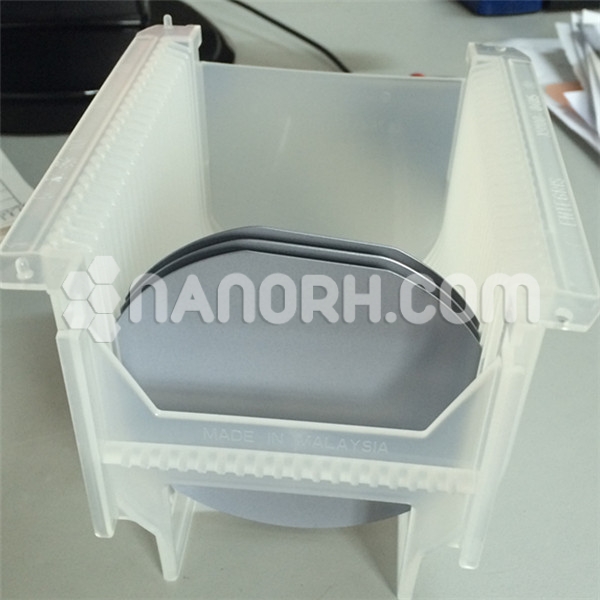

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Tin Tantalate Sputtering Targets

Introduction

Tin tantalate sputtering targets is a compound that combines tin oxide and tantalum oxide. It exhibits unique electrical, optical, and dielectric properties, making it a valuable material in various advanced applications. Tin tantalate is often utilized in thin-film deposition through sputtering, which allows for the precise control of film thickness and composition.

Applications

Dielectric Materials:

Tin tantalate is used in the fabrication of dielectric layers for capacitors and other electronic components. Its high dielectric constant and stability make it suitable for high-performance electronic applications.

Optoelectronic Devices:

Due to its optical properties, SnTaO₃ can be employed in optoelectronic devices such as light-emitting diodes (LEDs) and photodetectors. It is particularly useful in applications requiring high transparency and efficient light absorption.

Ferroelectric Applications:

Tin tantalate exhibits ferroelectric properties, making it suitable for use in ferroelectric random access memory (FeRAM) and other non-volatile memory technologies. Its ability to maintain polarization is valuable in memory applications.

Thin-Film Transistors (TFTs):

Tin tantalate can be utilized in thin-film transistors, which are critical components in display technologies, providing improved electrical performance and stability.

Piezoelectric Devices:

The piezoelectric properties of SnTaO₃ make it suitable for applications in sensors and actuators, where mechanical stress can be converted to electrical signals and vice versa.

Catalytic Applications:

Tin tantalate can also be explored as a catalyst or catalyst support in various chemical reactions, particularly in photocatalytic processes for environmental remediation.

Sputtering Process

The sputtering process for tin tantalate involves using a SnTaO₃ target in a vacuum chamber. When bombarded with energetic ions, atoms from the target are ejected and deposited onto a substrate, forming a thin film.