| Strontium Iron Oxide Sputtering Targets | |

| Product No | NRE-43554 |

| CAS No. | NA |

| Formula | SrFeO |

| Molecular Weight | NA |

| Purity | >99.9% |

| Density | NA |

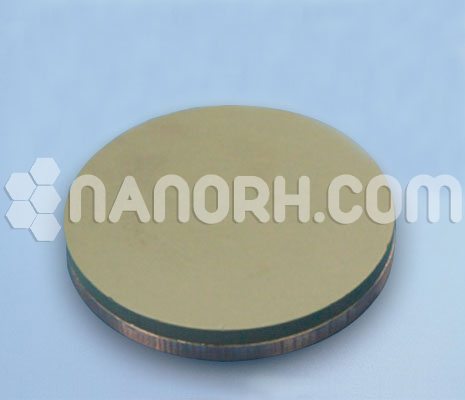

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Strontium Iron Oxide Sputtering Targets

Strontium iron oxide (SrFeO₃) sputtering targets are used in various applications, particularly in thin film deposition processes. Here’s an overview of their introduction and applications.

Introduction

Strontium iron oxide is a complex oxide that exhibits interesting electrical and magnetic properties. It belongs to the family of perovskite oxides, characterized by a crystal structure that contributes to its unique functionalities. SrFeO₃ is often used in applications related to:

Electrochemical Devices: Due to its high ionic conductivity, it is used in solid oxide fuel cells (SOFCs) and other electrochemical devices.

Magnetic Materials: Its magnetic properties make it suitable for applications in spintronics and other advanced magnetic devices.

Catalysis: SrFeO₃ can also serve as a catalyst in various chemical reactions, including those in environmental applications.

Applications

Thin Film Deposition: SrFeO₃ sputtering targets are used in the deposition of thin films for electronic components, sensors, and coatings. The films can be applied to substrates for enhanced performance in devices.

Solar Cells: The material can be incorporated into solar cell designs, particularly in perovskite solar cells, due to its ability to improve charge transport and efficiency.

Magnetoelectric Devices: The unique coupling of electric and magnetic properties in SrFeO₃ makes it valuable for devices that utilize magnetoelectric effects, which can be applied in data storage and conversion technologies.

Catalysis: Sputtered films of strontium iron oxide can enhance catalytic performance in various chemical reactions, such as those in environmental remediation or energy conversion.

Sensors: The material’s sensitivity to changes in temperature and atmosphere makes it suitable for various sensing applications, including gas sensors.