| Molybdenum Selenide Sputtering Targets | |

| Product No | NRE-43502 |

| CAS No. | 12058-18-3 |

| Formula | MoSe2 |

| Molecular Weight | 253.86 |

| Purity | >99.9% |

| Density | 6.90 g/cm3 |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

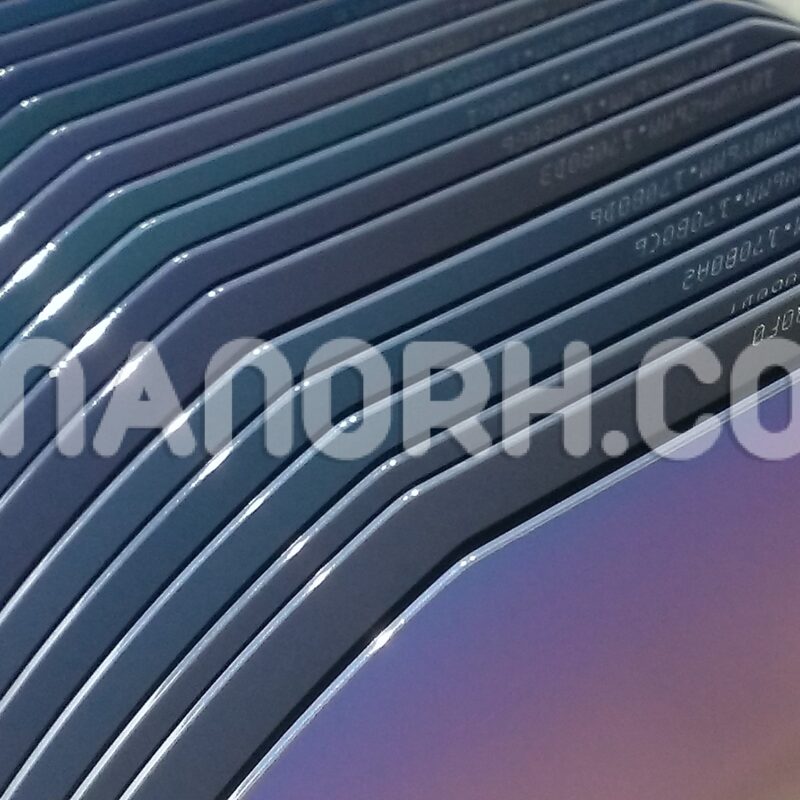

Molybdenum Selenide Sputtering Targets

Introduction

Molybdenum selenide sputtering targets are materials used in physical vapor deposition (PVD) processes to produce thin films of molybdenum selenide. MoSe₂ is a transition metal dichalcogenide (TMD) known for its layered structure and unique electronic, optical, and mechanical properties. This makes it a promising material for a variety of advanced applications.

Applications

Electronics:

Field-Effect Transistors (FETs): MoSe₂ is used as a channel material in FETs, particularly in flexible and low-power electronic devices.

Integrated Circuits: Its semiconducting properties make it suitable for various applications in integrated circuits.

Optoelectronics:

Photodetectors: MoSe₂ can be utilized in photodetectors that convert light into electrical signals, leveraging its unique optical properties.

Light-Emitting Devices: Employed in light-emitting devices and lasers due to its tunable bandgap.

Energy Storage:

Battery Applications: Molybdenum selenide can be used in electrode materials for lithium-ion batteries, enhancing energy storage capacity.

Supercapacitors: Investigated for use in supercapacitors to improve charge storage and efficiency.

Sensors:

Gas Sensors: MoSe₂ films are utilized in gas sensing applications, capitalizing on their sensitivity to environmental changes.

Chemical Sensors: Employed in chemical sensors for detecting various analytes.

Catalysis:

Hydrogen Evolution Reaction (HER): MoSe₂ has shown potential as a catalyst for HER, making it useful in sustainable energy applications.

Protective Coatings:

Used as a protective coating on various substrates, providing resistance to wear and corrosion.