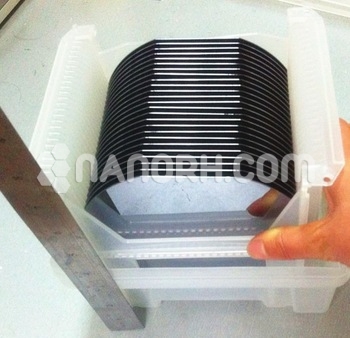

| Chromium Silicon Alloy Sputtering Targets | |

| Product No | NRE-43367 |

| CAS No. | NA |

| Formula | Cr-Si |

| Molecular Weight | NA |

| Purity | >99.9% |

| Density | NA |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Chromium Silicon Alloy Sputtering Targets

Chromium-silicon (Cr-Si) alloy sputtering targets are utilized in various advanced applications due to their combined properties of chromium and silicon. Here’s a detailed look at the different applications for Cr-Si alloy sputtering targets.

Semiconductor Fabrication

Diffusion Barriers: Cr-Si alloys are used as diffusion barriers in semiconductor devices to prevent the unwanted diffusion of elements between different layers, thereby maintaining the integrity and performance of the semiconductor devices.

Interconnects: They are employed in the deposition of interconnects in integrated circuits. The alloy’s properties help in forming reliable electrical connections with low resistance.

Thin Film Coatings

Wear-Resistant Coatings: The Cr-Si alloy provides excellent hardness and abrasion resistance. These coatings are used on tools, machinery parts, and other components subject to high wear and tear, extending their lifespan and performance.

Protective Coatings: The alloy offers good resistance to oxidation and corrosion, making it suitable for protective coatings in harsh environments.

Magnetic Materials

Magnetic Thin Films: Cr-Si alloy coatings can be used in the production of magnetic thin films for applications in magnetic storage devices and sensors. The alloy’s magnetic properties contribute to the performance and stability of these devices.

Optical Coatings

Anti-Reflective and Reflective Coatings: The Cr-Si alloy can be used in optical coatings to achieve specific optical properties, such as reflectivity and anti-reflectivity, which are important in various optical devices and components.

High-Temperature Applications

Thermal Stability: The alloy’s high thermal stability makes it suitable for applications involving high temperatures. This includes coatings and components in aerospace, energy production, and other high-temperature environments.

Decorative Coatings

Aesthetic Finishes: Cr-Si alloy coatings can be applied for decorative purposes, providing a unique finish and aesthetic appeal to consumer goods, automotive parts, and other products.

Tribological Applications

Friction Reduction: The alloy’s properties make it suitable for tribological applications where reducing friction and wear is critical, such as in bearings and sliding components.

Tool Coatings

Enhanced Tool Performance: Cr-Si alloy coatings are applied to cutting tools, drills, and other machining tools to enhance their hardness, wear resistance, and overall performance, especially under extreme conditions.