| Titanium Nitride Sputtering Target | |

| Product No | NRE-43162 |

| CAS No. | 25583-20-4 |

| Formula | TiN |

| Molecular Weight | 61.87 g/mol |

| Purity | 99.9% |

| Density | 5.24 g/cm3 |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Electrical Resistivity | NA |

| Electronegativity | NA |

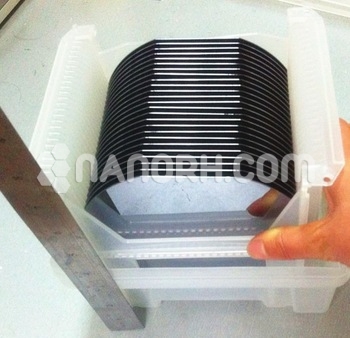

Titanium Nitride Sputtering Target

Introduction:

Titanium nitride sputtering target is a hard, ceramic material known for its excellent wear resistance, corrosion resistance, and distinctive gold-like appearance. TiN is often deposited as a thin film through physical vapor deposition (PVD) techniques, with sputtering being a common method. Sputtering targets made of TiN are used in various industries due to their ability to enhance surface properties of substrates.

Applications

Tool Coatings: TiN is widely used to coat cutting tools, dies, and molds to increase their hardness and reduce friction, leading to longer tool life and improved machining performance.

Biomedical Devices: TiN coatings can be applied to implants and surgical instruments, improving biocompatibility and reducing wear in biological environments.

Optical Coatings: In optics, TiN is used for thin film coatings that enhance durability and scratch resistance of lenses and other optical components.

Semiconductor Manufacturing: TiN is employed as a barrier layer in microelectronics to prevent diffusion of copper into silicon, thereby improving the performance and reliability of semiconductor devices.

Decorative Coatings: Due to its gold-like appearance, TiN is also used for decorative applications in jewelry, consumer electronics, and automotive parts, providing an aesthetic appeal along with protective properties.

Wear-Resistant Coatings: TiN coatings are applied to various components in automotive and aerospace industries to improve wear resistance and extend the life of parts exposed to harsh conditions.