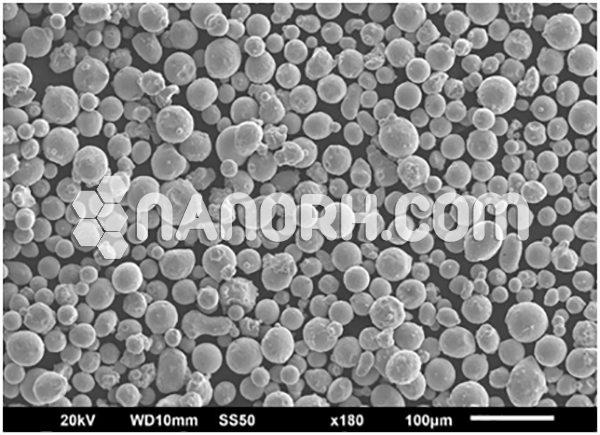

Grade 23 – Titanium 6Al-4V ELI Powder

The main application of 3D printing metal powder;

Aerospace

Molds

Automotive

Medical instruments

Military industry

| Product No. | Titanium Base Alloy Powder | Composition (%) | O (%) | A.D.g/cm3 | Particle Size |

| NRE-60009 | NRE-Ti90Al6V4 | Ti90Al6V4 | 0.15max | 3.8-4.8 | 0-15um, 15-45um,45-150um |

| NRE-CPTI | 0.15max | 0-15um, 15-45um,45-150um |

| CHEMICAL CONTENT (%) | |||

| Elements | Required | Measured | Observation |

| C | 0.08%max | 0.012% | Confirm |

| O | 0.10%max | 0.098% | Confirm |

| Y | 0.005%max | 0.004% | Confirm |

| Fe | 0.25%max | 0.025% | Confirm |

| V | 3.5-4.5% | 4.350% | Confirm |

| N | 0.03%max | 0.007% | Confirm |

| H | 0.012%max | 0.003% | Confirm |

| Al | 6-6.5% | 6.210% | Confirm |

| Ti | Bal. | Bal. | Confirm |

Grade 23 – Titanium 6Al-4V ELI Powder For 3D Printing

Applications

Aerospace Industry:

Structural Components: Grade 23 titanium 6Al-4V ELI powder for 3d printing is commonly used for producing lightweight, high-strength parts such as aircraft frames, wing structures, and engine components. The alloy’s excellent strength-to-weight ratio makes it perfect for these applications, where performance and fuel efficiency are paramount.

Turbine Parts: The alloy is used in turbine blades, vanes, and other critical parts for jet engines, which require materials that can withstand high temperatures and stress.

Heat Exchangers and Connectors: Due to its corrosion resistance and ability to handle extreme conditions, Ti-6Al-4V ELI is used in heat exchangers and connectors in the aerospace sector.

Medical Industry:

Medical Implants: Ti-6Al-4V ELI is a leading material in 3D printing for medical implants, such as hip implants, spinal implants, and knee replacements. Its biocompatibility reduces the risk of rejection, and its high strength ensures the longevity and functionality of implants.

Surgical Instruments: Grade 23 titanium is also used for medical tools and instruments, particularly those that require high durability and corrosion resistance, such as bone screws, surgical guides, and prosthetics.

Dental Implants: The alloy is used to manufacture dental implants due to its strength and ability to bond well with bone tissue, ensuring long-term stability.

Automotive Industry:

High-Performance Components: Titanium components in the automotive industry, particularly for high-performance cars or racing, benefit from the strength and lightness of Ti-6Al-4V ELI. Common parts include exhaust systems, engine components, and suspension elements, where weight reduction is critical without compromising durability.

Engine Components: Ti-6Al-4V ELI is used for turbocharger components and other engine parts, where the material’s ability to resist high temperatures and pressure is crucial.