AlSi10Mg Alloy Powder

The main application of 3D printing metal powder;

aerospace

molds

automotive

medical instruments

Military industry

| Product No. | Aluminum Alloy Powder | Composition (%) | O (%) | A.D.g/cm3 | Particle Size |

| NRE-60002 | NRE-AlSi10Mg | Si 9-11,Mg 0.3-0.5, Al Bal. | 0.05-0.15 | 0.8-1.8 | 15-53 µm, 20-60 µm, 30-80 µm, 45-105 µm, D50 10-15 µm, |

| NRE-AlSi7Mg | Si 6-8,Mg 0.3-0.5, Al Bal. | ||||

| NRE-AlSi12 | Si 11-13, Al Bal. | ||||

| NRE-AlMgScZr | Mg 5, Sc 0.6-0.8, Zr 0.3-0.5, Al Bal. | ||||

| NRE-5052 | Cu 5.8-6.8, Mn 0.2-0.4, Zr 0.1-0.25 Al Bal. | 0.9-1.9 | |||

| NRE-7075 | Mg 1-3, Mn 0.3 Al Bal. | 1.0-2.0 |

AlSi10Mg Alloy Powder

Introduction to AlSi10Mg Alloy Powder

AlSi10Mg is a high-performance aluminum-silicon-magnesium (Al-Si-Mg) alloy, known for its excellent combination of lightweight, high strength, corrosion resistance, and thermal stability. It is widely used in various manufacturing applications, particularly in industries that demand high-performance components with complex geometries and reduced weight. The alloy’s typical composition includes 90-96% aluminum, 8-12% silicon, and 0.3-1.0% magnesium, with the remaining percentage made up of trace elements, such as copper, iron, and zinc.

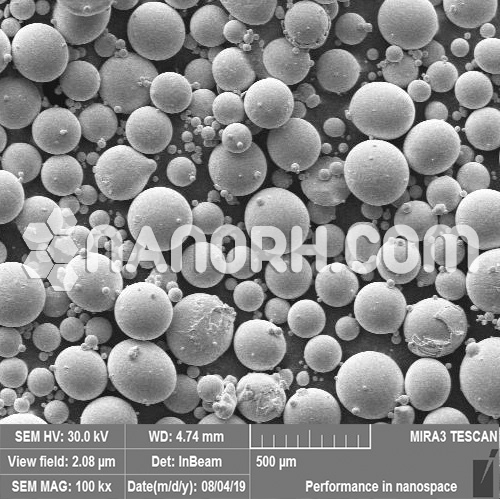

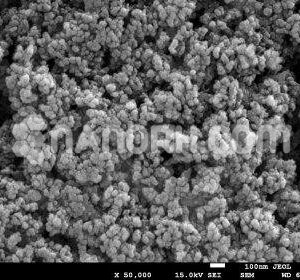

When processed into metal powder, AlSi10Mg powder is used for additive manufacturing (AM), particularly in Selective Laser Melting (SLM), Laser Powder Bed Fusion (L-PBF), and Electron Beam Melting (EBM) processes. These processes allow the alloy to be printed layer-by-layer to create parts with complex geometries and fine features that would be difficult or impossible to produce using conventional manufacturing methods like casting or machining. The powder’s spherical particle shape enhances flowability, packing density, and consistency, ensuring high-quality prints with minimal porosity.

Features of AlSi10Mg Alloy Powder

Lightweight:

AlSi10Mg is inherently lightweight due to the high aluminum content (about 90-96%). This makes it an ideal choice for industries where reducing weight is critical, such as aerospace, automotive, and sports equipment manufacturing. The low density of aluminum also results in reduced energy consumption and improved fuel efficiency in various applications.

High Strength-to-Weight Ratio:

The addition of silicon and magnesium to the alloy enhances its tensile strength and mechanical performance. Si improves the alloy’s strength, while Mg contributes to its hardness and heat resistance. This combination provides a high strength-to-weight ratio, making AlSi10Mg a suitable material for parts that require both strength and lightweight properties.