Aluminium Alloy Powder For 3D Printing

The main application of 3D printing metal powder;

aerospace

molds

automotive

medical instruments

| Product No. | Aluminum Alloy Powder | Composition (%) | O (%) | A.D.g/cm3 | Particle Size |

| NRE-60001 | NRE-AlMgScZr | Mg 4.5-5.0, Zr 0.2-0.4, Sc 0.6-0.8 Al Bal. | 0.05-0.15 | 0.8-1.8 | 15-53 µm , 20-60 µm , 30-80 µm , 45-105 µm , D50 10-15 µm , |

| NRE-AlCe | Ce 2-12, Al Bal. | ||||

| NRE-AlLa | La 2-12, Al Bal. | ||||

| NRE-AlY | Y 0.1-5, Al Bal. | ||||

| NRE-AlEr | Er 1-20 Al Bal. | 0.9-1.9 | |||

| NRE-Al rare earth | Rare earth 0.1-20 Al Bal. | 1.0-2.0 |

Aluminium Alloy Powder For 3D Printing

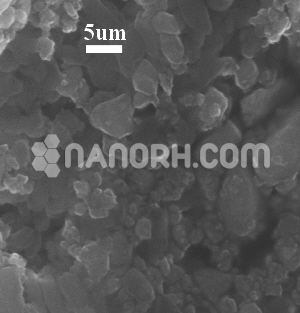

Aluminium alloy powders for 3d printing are crucial materials in the realm of 3D printing, particularly for Additive Manufacturing (AM) processes like Selective Laser Melting (SLM), Laser Powder Bed Fusion (L-PBF), and Electron Beam Melting (EBM). These powders are used to create lightweight, high-strength, and durable components with excellent thermal conductivity, corrosion resistance, and mechanical properties. Aluminium alloy powders, such as AlSi10Mg, Al-6061, and AlCu4Mg1, are particularly favored for 3D printing applications due to their ideal combination of properties that make them suitable for a wide range of industries.

Key Applications

Aerospace Industry:

Lightweight components are critical in aerospace, where fuel efficiency and performance depend on reducing weight without compromising strength. Aluminium alloys like AlSi10Mg are ideal for printing aircraft components, such as brackets, mounting frames, turbine blades, air ducts, and engine parts.

3D printing allows for the creation of complex geometries like internal cooling channels or hollow structures, optimizing the weight and strength of aerospace parts.

Additionally, AlSi10Mg offers good corrosion resistance, ensuring longevity even in harsh conditions, such as high-altitude flights or exposure to chemicals.

Automotive Industry:

Aluminium alloys are used extensively in the automotive industry for parts that require a high strength-to-weight ratio, such as engine blocks, intake manifolds, brackets, and chassis components.

The automotive industry benefits from 3D printing because it allows for the production of customized components and low-volume production of complex parts.

AlSi10Mg and other aluminium alloys also provide benefits in terms of heat dissipation and thermal management, which are essential for parts in engines and exhaust systems.

Industrial Manufacturing & Tooling:

3D printing with aluminium alloy powder is increasingly used to produce industrial tools, such as molds, fixtures, jigs, and casting patterns.

The ability to print complex shapes and internal cooling channels directly into tooling parts with additive manufacturing leads to significant improvements in performance and efficiency. For example, molds and casting cores benefit from the ability to have optimized cooling without the need for additional assembly or machining.