| Tantalum Hafnium Carbide Nanoparticles | |

| Product No | NRE-5215 |

| CAS | 71243-79-3 |

| Purity | 99.9% |

| Formula | TaC/HfC |

| APS | <100 nm (can be customized) |

| Color | Gray black |

| Molecular Weight | 962.34 g/mol |

| Density | NA |

| Melting Point | 3990 °C |

| Boiling Point | NA |

Tantalum Hafnium Carbide Nanoparticles

Introduction

Tantalum Hafnium Carbide (TaHfC) nanoparticles are advanced materials composed of tantalum (Ta), hafnium (Hf), and carbon (C). They are a member of the family of refractory ceramics, known for their exceptional properties, including very high melting points, outstanding hardness, excellent thermal stability, and remarkable chemical resistance. The combination of tantalum and hafnium, both of which are transition metals, leads to a unique carbide compound that outperforms many other materials, particularly in extreme environments.

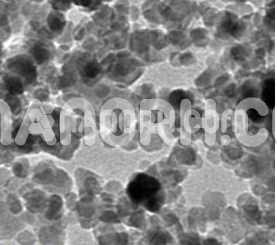

TaHfC nanoparticles represent the nanoscale form of this compound, which means they have an increased surface area compared to bulk materials. This nanostructure results in enhanced reactivity and other improved properties, such as higher thermal conductivity and mechanical strength. Due to these features, TaHfC nanoparticles are of interest in a wide range of high-performance applications, especially those requiring materials to operate at extreme temperatures, under heavy mechanical stress, or in chemically aggressive environments.

Properties

Extremely High Melting Point: TaHfC nanoparticles have an extremely high melting point, typically in the range of 4,000 to 4,100°C, making them suitable for applications in environments where most materials would fail. This is one of the highest known melting points for any material, which makes TaHfC particularly useful in aerospace and nuclear technologies, where high-temperature performance is crucial.

Hardness and Wear Resistance: Both tantalum carbide (TaC) and hafnium carbide (HfC) are hard materials, and when combined in TaHfC nanoparticles, they form an even harder compound. The result is a material that is extremely resistant to wear and abrasion, making it ideal for cutting tools, abrasive coatings, and other materials exposed to high levels of mechanical stress.

Thermal Conductivity: TaHfC nanoparticles exhibit excellent thermal conductivity, allowing them to efficiently transfer heat. This property is important in applications where heat dissipation is critical, such as in aerospace components, nuclear reactors, and energy storage devices.

Chemical Stability: TaHfC is chemically stable and highly resistant to oxidation, even at high temperatures. This makes TaHfC nanoparticles suitable for use in corrosive environments, such as in chemical processing and high-temperature manufacturing.

Electrical Conductivity: TaHfC nanoparticles also show good electrical conductivity, making them suitable for applications in electronics and energy systems, where electrical efficiency is important.

Nanostructure: The nanoscale form of TaHfC enhances the material’s surface area and reactivity. This is especially beneficial for applications like catalysis and energy storage, where high surface area can improve performance.