| NiTi50 Alloy Spherical Powder | |

| Product No | NRE-9084 |

| CAS | 52013-44-2 |

| Purity | 99.9% |

| Formula | NiTi50 |

| APS | 200 mesh |

| Colour | Grey |

| Density | 6.45 g/cm3 |

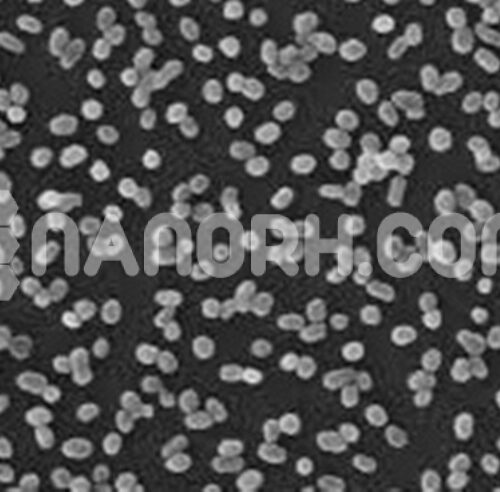

| Shape | Spherical |

| Melting Point | NA |

| Boiling Point | NA |

NiTi50 Alloy Spherical Powder

Introduction

NiTi50 alloy spherical powder is a type of Nickel-Titanium (Ni-Ti) alloy powder, which contains a 50% nickel and 50% titanium composition. This specific ratio of nickel to titanium is commonly used in the production of shape memory alloys (SMAs), which exhibit unique properties like shape memory effect (SME) and superelasticity.

Applications

Medical and Biomedical Applications:

Medical Implants: NiTi50 alloy is widely used in medical implants due to its biocompatibility and corrosion resistance. Common implants include stents, bone staples, and orthopedic devices. The shape memory effect of NiTi allows the implants to conform to the body’s natural shape after insertion, improving patient outcomes.

Orthodontic Wires: The alloy is used in dental devices, particularly in orthodontic wires, as its superelasticity allows it to apply consistent force to move teeth into alignment.

Surgical Instruments: NiTi50 alloy is used in guidewires, catheters, and other surgical tools that require flexibility, precision, and resistance to fatigue.

Stents and Cardiovascular Devices: NiTi50 is used in the manufacture of vascular stents, which can expand and conform to the shape of blood vessels, allowing for improved blood flow in arteries.

Aerospace and Defense:

Actuators: The shape memory effect and superelasticity of NiTi50 alloys make them ideal for use in aerospace actuators. These actuators can change shape in response to temperature changes or stress, enabling precise control in applications such as satellite mechanisms and deployable structures.

Shape Memory Alloys for Smart Structures: The alloy is used in smart materials and structures for aerospace and defense applications. These materials can adjust their shape in response to changes in temperature, providing adaptive functionality in dynamic environments.

Automotive Industry:

Clutch Springs and Shock Absorbers: NiTi50 alloy’s superelasticity is used in automotive components such as clutch springs and shock absorbers, which need to absorb shocks and return to their original shape repeatedly without permanent deformation.