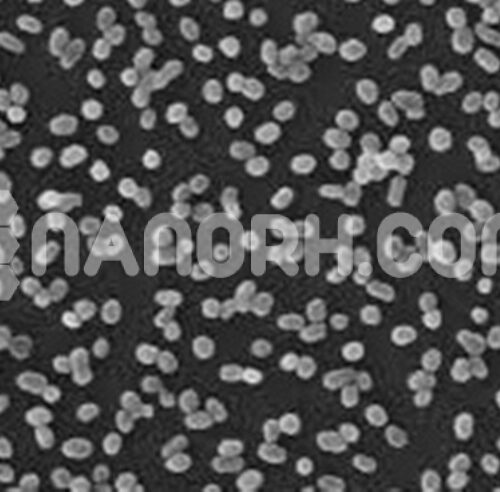

Titanium Spherical Powder

Titanium is a chemical element with the symbol Ti and atomic number 22. It is a brilliant transition metal with a silvery color, low density, and high strength. Titanium is corrosion resistant in seawater, water regime, and chlorine.

Titanium was discovered in Cornwall, Great Britain by William Gregor in 1791, and was named by Martin Heinrich Klaproth for the titans of Greek mythology. The element is within a range of minerals, particularly rutile and ilmenite deposits, which are widely distributed in the crust and the Earth’s lithosphere, and is found in almost all living things, bodies of water, rocks, and soils. The metal is extracted from its main mineral minerals by the processes of Kroll and Hunter.

| Titanium Spherical Powder | |

| Product No | NRE-8052 |

| CAS | 7440-32-6 |

| Purity | 99.9% |

| Formula | Ti |

| APS | <40um (can be customized) |

| Color | Dark grey |

| Molecular Weight | 47.867 g/mol |

| Density | 4.506 g/cm3 |

| Melting Point | 1668 °C |

| Boiling Point | 3287 °C |

Titanium Spherical Powder

Titanium powder has a wide range of applications in various industries due to its unique properties. It is a lightweight, strong, and corrosion-resistant material, making it highly sought after for several purposes. Some common applications of titanium powder include:

Additive Manufacturing: Titanium powder is extensively used in additive manufacturing, also known as 3D printing, to produce complex and intricate components, especially in the aerospace and automotive industries. Its high strength-to-weight ratio and corrosion resistance make it an ideal choice for producing lightweight yet durable parts.

Aerospace Industry: Titanium powder is a crucial material in the aerospace industry due to its excellent strength-to-weight ratio. It is used to manufacture components such as aircraft engines, structural components, and landing gears. Its resistance to extreme temperatures and corrosion also makes it suitable for aerospace applications.

Biomedical Implants: Titanium powder is biocompatible, making it suitable for medical applications, including the production of implants such as joint replacements, dental implants, and bone plates. Its biocompatibility ensures that the body accepts the implant without any adverse reactions.

Chemical Processing: Titanium powder is used in various chemical processes due to its corrosion resistance, especially in environments where other metals would corrode. It finds applications in equipment for handling corrosive substances, such as acids and chlorine.

Automotive Industry: Titanium powder is used in the automotive industry for manufacturing lightweight components that contribute to fuel efficiency. It is used in exhaust systems, connecting rods, and valve springs due to its strength, corrosion resistance, and heat resistance.

Sports Equipment: Titanium powder is used in the production of sports equipment such as bicycles, golf clubs, and tennis rackets. Its lightweight nature and high strength make it an ideal material for enhancing performance and durability in sports equipment.

Marine Industry: Titanium powder is utilized in the marine industry for various applications, including the manufacturing of offshore oil and gas equipment, ship components, and underwater pipelines. Its corrosion resistance in saltwater environments makes it a preferred material for marine applications.

Architectural Applications: Titanium powder is also used in architecture for creating durable and corrosion-resistant structures. It is used in the construction of bridges, buildings, and other structures where corrosion and durability are major concerns.