| Titanium Aluminum Vanadium Alloy | |

| Product No | NRE-9091 |

| CAS No. | 7429-32-6 / 7429-90-5 / 7440-62-2 |

| Formula | Ti6Al4V |

| Molecular Weight | NA |

| APS | <40 um (Can be Customized) |

| Purity | 99.9% |

| Density | 4.43 g/cm3 |

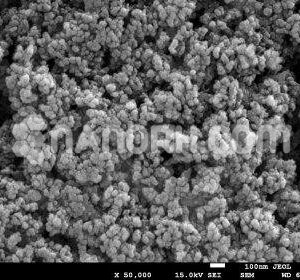

| Color | Gray |

| Melting Point | 1604-1660 °C |

| Boiling Point | NA |

Titanium Aluminum Vanadium Alloy

Titanium Aluminum Vanadium Alloy

Titanium Aluminum Vanadium (TiAlV) alloys are a class of high-performance materials known for their exceptional combination of lightweight, high strength, and high-temperature resistance. These alloys are commonly used in industries where performance under extreme conditions is paramount, such as in aerospace, automotive, medical, and military applications.

Composition and Properties of TiAlV Alloy

Key Elements in TiAlV Alloy:

Titanium (Ti): The base element of the alloy, titanium is a transition metal known for its excellent strength-to-weight ratio and high corrosion resistance. It provides the alloy with lightweight characteristics and excellent resistance to oxidation, especially in high-temperature environments.

Aluminum (Al): Aluminum is added to improve the strength, creep resistance, and thermal stability of the alloy. Aluminum also enhances the alloy’s oxidation resistance and increases its overall temperature tolerance, making it more suitable for high-temperature applications such as those found in aerospace and automotive industries.

Vanadium (V): Vanadium is used to stabilize the titanium alloy’s microstructure, particularly at elevated temperatures. It enhances the strength, hardness, and ductility of the alloy and contributes to its overall toughness. Vanadium also aids in controlling the grain structure of the alloy, improving its mechanical properties.

Key Properties of TiAlV Alloys

High Strength-to-Weight Ratio: One of the most notable properties of titanium alloys, including TiAlV, is their exceptional strength-to-weight ratio. This is particularly beneficial in industries like aerospace and automotive, where weight reduction is essential for improving fuel efficiency, performance, and reducing emissions.

High-Temperature Resistance: TiAlV alloys maintain their structural integrity and mechanical properties even at elevated temperatures. This makes them ideal for applications where components are subjected to heat, such as in turbine engines, exhaust systems, and aerospace components.