| Tungsten Carbide Cobalt Alloy Nanoparticles | |

| Product Number | NRE-2057 |

| CAS No. | 12070-12-1 / 7440-48-4 |

| Formula | WC-Co |

| Molecular Weight | 254.78 / g/mol |

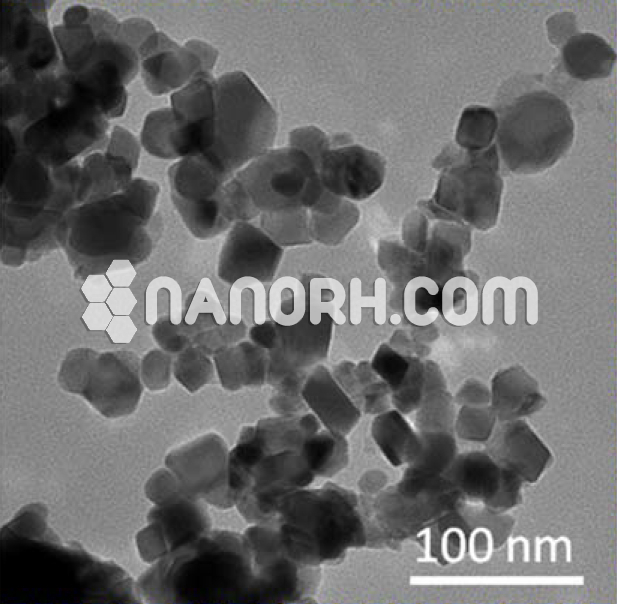

| APS | <100 nm (Can be Customized) |

| Purity | 99.9% |

| Colour | Gray |

| Density | Na |

| Melting Point | Na |

| Boiling Point | Na |

Tungsten Carbide Cobalt Alloy Nanoparticles

Applications

Cutting Tools and Machining:

Drills, Mills, and End Mills: WC-Co nanoparticles are widely used in the production of cutting tools for machining metals, wood, and plastics. The hardness of tungsten carbide combined with the toughness of cobalt results in tools that can withstand the high stresses and wear associated with cutting and machining operations.

Abrasive Tools: The hardness and wear resistance of WC-Co nanoparticles make them ideal for abrasive tools such as grinding wheels, saw blades, and polishing pads used in manufacturing processes.

Mining and Drilling:

Mining Tools: The extreme hardness and wear resistance of WC-Co nanoparticles make them perfect for use in mining tools, including drill bits, crushers, and ground-engaging tools. These nanoparticles help mining equipment last longer and perform more effectively in abrasive environments.

Wear-Resistant Coatings:

Surface Coatings: WC-Co nanoparticles can be applied as coatings to other materials to improve their wear resistance, especially in machinery and tools that experience high friction. The coatings are used in industries such as automotive, aerospace, and manufacturing to protect parts from wear and tear, extending the lifespan of expensive equipment.

Bushing and Bearings: The wear-resistant properties of WC-Co nanoparticles are also useful in producing bushings and bearings that need to operate smoothly under heavy loads and high stress.

Automotive Industry:

Engine Components: WC-Co nanoparticles are used in automotive applications to produce components such as pistons, valve seats, and camshafts, where high wear resistance and strength are essential for performance and longevity.

Aerospace and Defense:

Turbine Blades and Engine Parts: WC-Co nanoparticles are employed in aerospace for turbine blades and other engine components, which are subjected to high mechanical stresses and elevated temperatures. These alloys provide the necessary durability and heat resistance in critical aerospace applications.