Titanium Tantalum Carbide Tungsten Carbide Alloy Nanoparticles

Titanium Tantalum Carbide Tungsten Carbide Alloy Nanoparticles

Titanium Tantalum Carbide Tungsten Carbide Alloy Nanoparticles

| Titanium Tantalum Carbide Tungsten Carbide Alloy Nanoparticles | |

| Product Number | NRE-2054 |

| CAS No. | 7440-32-6/12070-06-3/12070-12-1 |

| Formula | Ti-TaC-WC |

| Molecular Weight | 436.67 / g/mol |

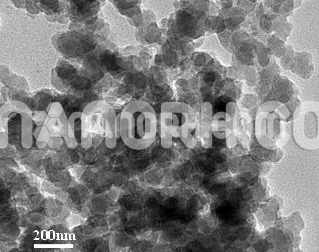

| APS | <100 nm (Can be Customized) |

| Purity | 99.9% |

| Colour | Gray |

| Density | Na |

| Melting Point | Na |

| Boiling Point | Na |

Titanium Tantalum Carbide Tungsten Carbide Alloy Nanoparticles

Introduction

Titanium-Tantalum Carbide Tungsten Carbide (Ti-TaC-WC) alloy nanoparticles represent a class of advanced materials that combine the unique properties of titanium, tantalum, tungsten, and carbon in a composite form at the nanoscale. These materials have garnered significant attention in various scientific fields due to their exceptional mechanical, thermal, and chemical properties, which are enhanced when reduced to nanoparticle form.

Components of the Ti-TaC-WC Nanoparticle Alloy:

Titanium (Ti):

Properties: Titanium is a lightweight, corrosion-resistant metal known for its strength, excellent biocompatibility, and high melting point. When incorporated into an alloy, titanium enhances the overall structural integrity and resistance to environmental degradation.

Role in the Alloy: Titanium contributes to the alloy’s excellent strength-to-weight ratio, resistance to corrosion, and ability to withstand high temperatures. Titanium also adds to the material’s high hardness, making it useful in abrasive environments.

Tantalum (Ta):

Properties: Tantalum is a refractory metal that is extremely resistant to corrosion and oxidation, even at high temperatures. It has high ductility, good conductivity, and excellent resistance to acids and other reactive chemicals.

Role in the Alloy: Tantalum is included in the alloy for its exceptional resistance to corrosion and high-temperature stability. It also contributes to improving the overall strength and wear resistance of the composite, particularly under extreme conditions.

Tungsten (W):

Properties: Tungsten is one of the densest and hardest metals known, with a very high melting point (over 3,400°C). It is also highly resistant to wear and corrosion and has excellent thermal conductivity.

Role in the Alloy: Tungsten is used in Ti-TaC-WC nanoparticles for its hardness, wear resistance, and ability to maintain structural integrity under high-temperature and high-stress conditions. Tungsten improves the alloy’s mechanical properties and enhances its performance in applications requiring toughness and resistance to mechanical deformation.