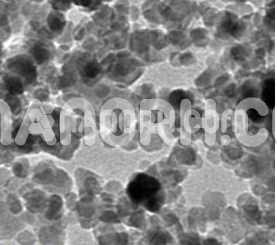

Iron Vanadium Alloy Nanoparticles

| Iron Vanadium Alloy Nanoparticles | |

| Product Number | NRE-2027 |

| CAS No. | 12604-58-9 |

| Formula | Fe-V |

| Molecular Weight | 106.78 g/mol |

| APS | <100 nm (Can be Customized) |

| Purity | 99.9% |

| Colour | Gray |

| Density | Na |

| Melting Point | 1,480 °C |

| Boiling Point | Na |

Iron Vanadium Alloy Nanoparticles

Applications

Wear-Resistant Coatings:

Fe-V alloy nanoparticles are often used in the production of wear-resistant coatings for high-performance mechanical components such as cutting tools, bearings, gears, and engine parts. The enhanced hardness and resistance to abrasion make these nanoparticles ideal for use in industries that require durable materials exposed to wear and friction.

Automotive and aerospace industries benefit from these coatings for parts that must endure high mechanical stresses and maintain their functionality over time.

Magnetic Materials:

Due to the ferromagnetic nature of iron, Fe-V alloy nanoparticles are used in magnetic storage devices (e.g., hard drives, magnetic tapes) and magnetic sensors. These applications benefit from the magnetic properties of the nanoparticles, which enable the creation of more efficient and compact magnetic devices.

Fe-V nanoparticles are also explored for use in magnetic resonance imaging (MRI), where their magnetic properties can enhance imaging quality and provide better contrast.

Catalysis:

Fe-V alloy nanoparticles exhibit enhanced catalytic activity, making them suitable for use in various chemical reactions such as hydrogenation, oxidation, and dehydrogenation processes. They are used in industrial applications where efficient catalysis is crucial, such as petrochemical refining, hydrogen production, and environmental cleanup.

The combination of iron’s reactivity and vanadium’s catalytic properties makes Fe-V nanoparticles useful in developing more efficient fuel cells and battery technologies.

High-Strength Structural Materials:

Fe-V alloy nanoparticles are employed in the development of high-strength steels and lightweight structural materials for use in construction, mining, and automotive industries. The alloy’s ability to withstand high stresses while maintaining structural integrity makes it suitable for use in machinery, vehicles, and infrastructure.

Aerospace applications also benefit from the strength and durability of these alloys in components that need to endure extreme conditions without compromising performance.