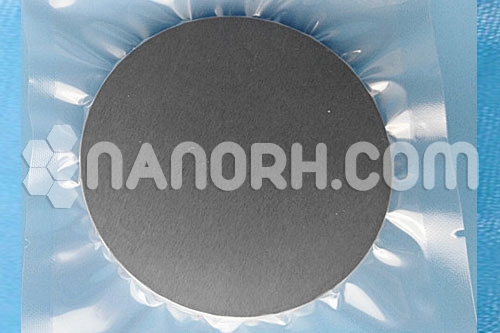

| Molybdenum Oxide Sputtering Target | |

| Product No | NRE-43107 |

| CAS No. | 1313-27-5 |

| Formula | MoO3 |

| Molecular Weight | 143.94 g/mol |

| Purity | 99.99% |

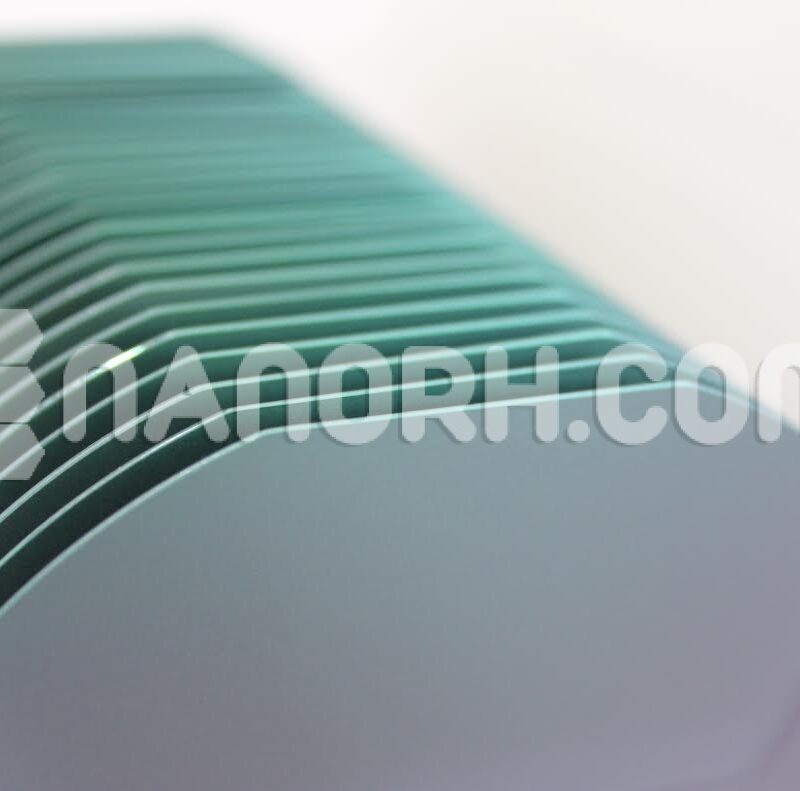

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

Molybdenum Oxide Sputtering Target

Introduction

Molybdenum oxide (MoOₓ) sputtering targets are materials used in physical vapor deposition (PVD) processes to create thin films of molybdenum oxide, which can exist in various oxidation states such as MoO, MoO₂, and MoO₃. These compounds are known for their unique electrical, optical, and catalytic properties, making them valuable in a range of technological applications.

Applications of Molybdenum Oxide Sputtering Targets

Electronics:

Thin Film Transistors (TFTs): Used as active layers in TFTs, particularly in display technology, benefiting from their semiconducting properties.

Conductive Layers: Employed as conductive films in various electronic devices, providing a stable and reliable electrical connection.

Optoelectronics:

Transparent Conductive Oxides (TCOs): MoOₓ films can function as transparent conductive layers in solar cells and displays, enhancing performance while maintaining transparency.

Photodetectors: Used in the fabrication of photodetectors that convert light into electrical signals.

Catalysis:

Catalytic Converters: Molybdenum oxide is used in catalytic converters in automotive applications facilitate oxidation reactions and reduce emissions.

Chemical Reactions: Employed in various catalytic processes in the chemical industry due to its effective oxidation capabilities.

Energy Storage:

Battery Applications: Molybdenum oxides can be used in electrode materials for batteries, contributing to improved energy storage and efficiency.

Supercapacitors: Investigated for use in supercapacitors, enhancing charge storage capabilities.

Protective Coatings:

MoOₓ films can serve as protective coatings, providing resistance to corrosion and wear, thus extending the lifespan of components.

Sensors:

Gas Sensors: Molybdenum oxide films are utilized in gas sensors, leveraging their sensitivity to changes in the environment.