| Mullite Nanoparticles | |

| Product No. | NRE-6022 |

| CAS No. | 1302-93-8 |

| Formula | 3Al2O32SiO2 |

| Molecular Weight | 426.05 g/mol |

| APS | < 100 nm |

| Purity | 99.9% |

| Form | Powder |

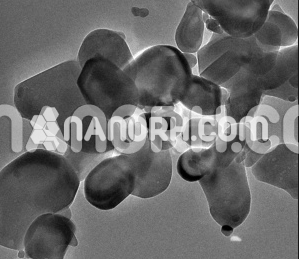

Mullite Nanoparticles

Mullite (3Al2O3.2SiO2), as a stable compound, is often used as a refracting and structural material for high temperature applications due to its excellent properties such as high melting point, low flow rate, minimal thermal conductivity and high strength. to thermal shock.

Due to its low dielectric constant, mullite is also a good substrate for electronic circuits. On the other hand, its usual compact structure hinders the development of certain characteristics and limits its potential applications.

Adding high porosity to mullite ceramic can impart unexpected properties, including low bulk density, high specific area, low thermal conductivity, and low dielectric constant. Mullite nanofiber airgels are best suited for lightweight insulation materials.

Due to the open porous structure of mullite, ceramic foam is widely used as shields for high temperature gases and liquids, separation films and catalyst carriers.

The porous mullite ceramics were produced using various techniques such as reaction sintering, freeze drying, foam or emulsion modeling, adding replicas of the pore-forming method, gel casting and 3D printing.

Unfortunately, hardly any products made with these products have a porosity greater than 80%. It is critical to develop a successful process to produce high porosity mullite ceramic foam without sacrificing compressive strength, but that remains the goal.