| Organically Modified Montmorillonite Nanoclay [OMMT] | |

| Product No | NRE-6025 |

| CAS No. | 1318-93-0 |

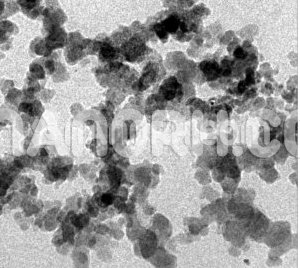

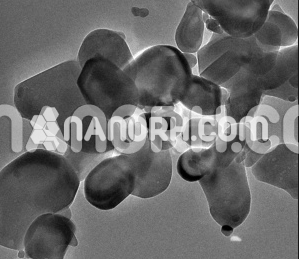

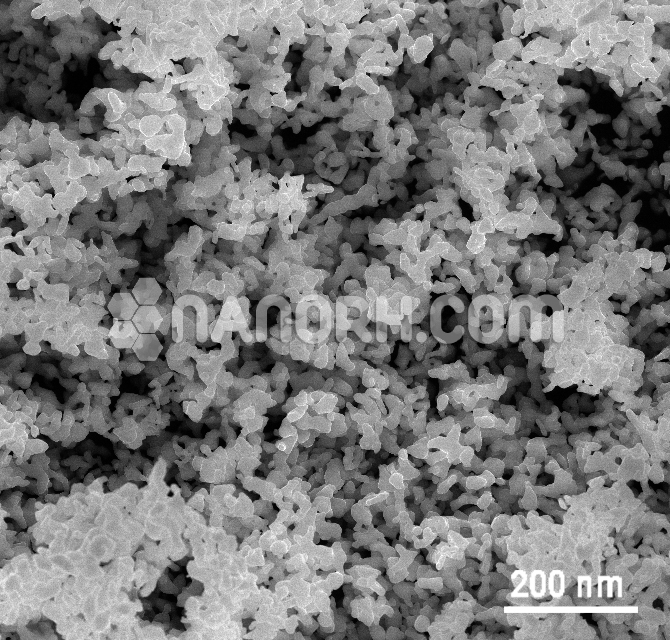

| Formula | Al2[(OH)2|Si4O10].nH2O |

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | Beige-tan |

| Molecular Weight | 360.31 g/mol |

| Density | 1.7-2.7g/cm3 |

| Melting Point | NA |

| Boiling Point | NA |

OMMT

Introduction

OMMT (Organically Modified Montmorillonite) is a modified form of montmorillonite clay, which is a type of smectite clay with a layered structure. Montmorillonite is naturally abundant and widely used in industrial applications due to its high surface area, layered silicate structure, and swelling properties in the presence of water. However, in its natural state, montmorillonite tends to be poorly compatible with non-polar organic materials like polymers, asphalts, and oils.

Applications

Polymer Nanocomposites

Polymer Reinforcement:

OMMT is widely used as a nanofiller to reinforce various polymers such as polyethylene (PE), polypropylene (PP), polystyrene (PS), epoxy, and nylon. When OMMT is added to these polymers, it improves tensile strength, flexural modulus, impact resistance, and heat deflection temperature.

Improved Barrier Properties:

The high aspect ratio and nano-dispersion of OMMT in polymer matrices improve gas barrier properties, moisture resistance, and chemical resistance, making these materials ideal for food packaging, medical products, and protective coatings.

Lightweight Composites:

By incorporating OMMT into composite materials, industries can develop lightweight yet strong materials. This is particularly important in industries like automotive, aerospace, and construction, where reducing weight without sacrificing strength is crucial.

Asphalt and Road Construction

Improved Asphalt Performance:

OMMT is used to enhance the properties of asphalt for road construction. It improves rutting resistance, thermal stability, crack resistance, and flexibility, making it ideal for high-performance pavements in high-traffic areas, airports, and highways.

Water and Moisture Resistance:

OMMT-modified asphalt has enhanced hydrophobicity and moisture resistance, reducing the risk of water stripping and improving the durability of roads under wet conditions.

Sustainability:

The incorporation of OMMT in asphalt can reduce the need for frequent road repairs and maintenance, leading to longer-lasting roads and reducing the environmental footprint of road construction projects.

Paints, Coatings, and Adhesives

Durable Coatings:

OMMT is used to improve the mechanical properties of paints and coatings. It increases the scratch resistance, abrasion resistance, chemical resistance, and weatherability of coatings, making them ideal for automotive finishes, marine coatings, and industrial coatings.

UV Stability:

OMMT-modified coatings offer improved UV resistance, preventing degradation, discoloration, or fading due to prolonged exposure to sunlight. This is especially important for outdoor applications, such as building facades, furniture, and automotive parts.

Enhanced Adhesion:

OMMT is also used in adhesives to enhance their bonding strength, durability, and performance under extreme conditions, such as temperature fluctuations and moisture exposure.