| Nickel Chromium Alloy Powder | |

| Product No | NRE-9026 |

| CAS No. | 11106-97-1 |

| Formula | Ni-Cr |

| Molecular Weight | 110.6895 g/mol |

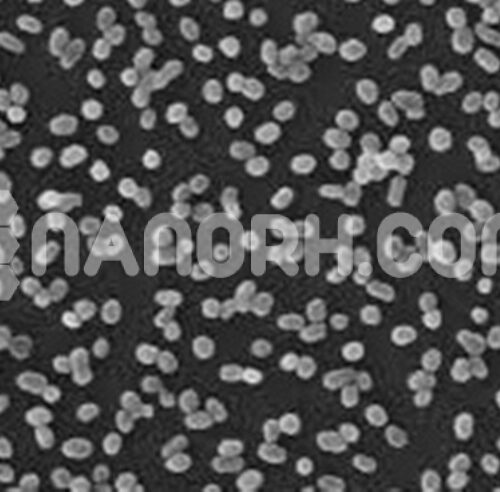

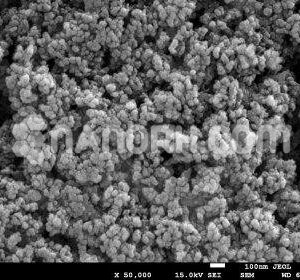

| APS | <40 um (Can be Customized) |

| Purity | 99.9% |

| Density | NA |

| Color | Gray |

| Melting Point | 1400°C |

| Boiling Point | NA |

Nickel Chromium Alloy Powder

Applications

Thermal Spraying and Coatings:

Ni-Cr alloy powder is widely used in thermal spray coating technologies such as flame spraying, plasma spraying, and high-velocity oxy-fuel (HVOF) spraying. These coatings are applied to a wide range of substrates to provide oxidation resistance, abrasion resistance, and corrosion protection. Common applications include coating turbine blades, engine components, heat exchangers, and pipes in the aerospace, power generation, and chemical processing industries.

Additive Manufacturing (3D Printing):

Ni-Cr alloy powder is used in additive manufacturing processes such as Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS). In these processes, the powder is melted layer by layer to form complex, highly durable parts for industries like aerospace, automotive, and medical devices. The alloy’s high-temperature stability and corrosion resistance make it suitable for manufacturing components like engine parts, turbine blades, and heat exchangers that require precise mechanical properties.

Welding and Brazing:

Ni-Cr alloy powder is used as a filler material in welding and brazing applications, where it helps create strong, durable joints between metals. It is especially useful in joining high-performance materials like stainless steel, titanium, and high-temperature alloys. The addition of chromium improves the alloy’s ability to withstand oxidation and corrosion in challenging environments.

Electronics and Heating Elements:

Nickel-Chromium alloys are commonly used in the production of heating elements and resistors due to their ability to withstand high temperatures and maintain stable electrical properties. In particular, they are used in electric furnaces, ovens, water heaters, and toasters. The combination of oxidation resistance and high-temperature performance makes Ni-Cr alloys ideal for heating applications.

Gas Turbines and Jet Engines:

Ni-Cr alloys are extensively used in gas turbines and jet engines, where high-temperature strength and oxidation resistance are crucial.